100ml ka ho iketsa Oli e Tlatsang Oli e Tlatsang Capping Machine Line ka libotlolong

Melemo

E loketse lintho tse bonahalang: lisebelisoa tsa letsatsi le letsatsi tsa viscosity tsa lik'hemik'hale.

1. Tekanyo e nepahetseng: amohela sistimi ea taolo ea servo, etsa bonnete ba hore piston e ka fihla maemong a sa feleng

2. Ho tlatsoa ka lebelo le feto-fetohang: ts'ebetsong ea ho tlatsa, ha o le haufi le sepheo sa ho tlatsa sepheo se ka sebelisoa ho hlokomela ho tlatsa butle butle, ho thibela molomo oa botlolo oa metsi ho baka tšilafalo.

3. Phetoho e bonolo: lintlha tse tlatsitsoeng tse tlatsitsoeng feela skrineng se ts'oaroang li ka fetoloa ka liparamente, 'me tsohle li tlatsa phetoho ea pele ea boemo, ho e lokisa hantle ka tokiso ea skrineng ea ho ama Adopt servo motor ho theoha.

4. Ho khetha tlhophiso ea likarolo tsa motlakase tse tsebahalang tsa machaba.Khomphuta ea Mitsubishi Japan PLC, omron photoelectric, Taiwan e hlahisoa skrineng sa ho ama, ho netefatsa boleng ba eona bo ikhethang ka ts'ebetso ea nako e telele.

| Lintho tse bonahalang | SS304/316L |

| Boitsebiso ba Botlolo | PET/PE/PP/Glass/Tšepe |

| Sebopeho sa Botlolo | Round/Square/Unique Square |

| Mokhoa oa Capping | Screw cap, Tobetsa cap, Twisting Cap |

| Likarolo tsa Botlolo | Phetoho e potlakileng ntle le lisebelisoa, joalo ka mabili a linaleli bakeng sa infeed ea botlolo le outfeed, le li-clamps tsa bottleneck |

| Sistimi ea Taolo | PLC le skrine ea ho ama |

| Ho Filing Precision | ±1% |

| Lintho tse tlatsang | Oli, oli ea ho pheha, oli ea enjine joalo-joalo. |

| Phepelo ea motlakase | 220V/380V 50/60HZ |

| Ho Tlatsa Lebelo | 1000-6000 libotlolo ka hora (Customized) |

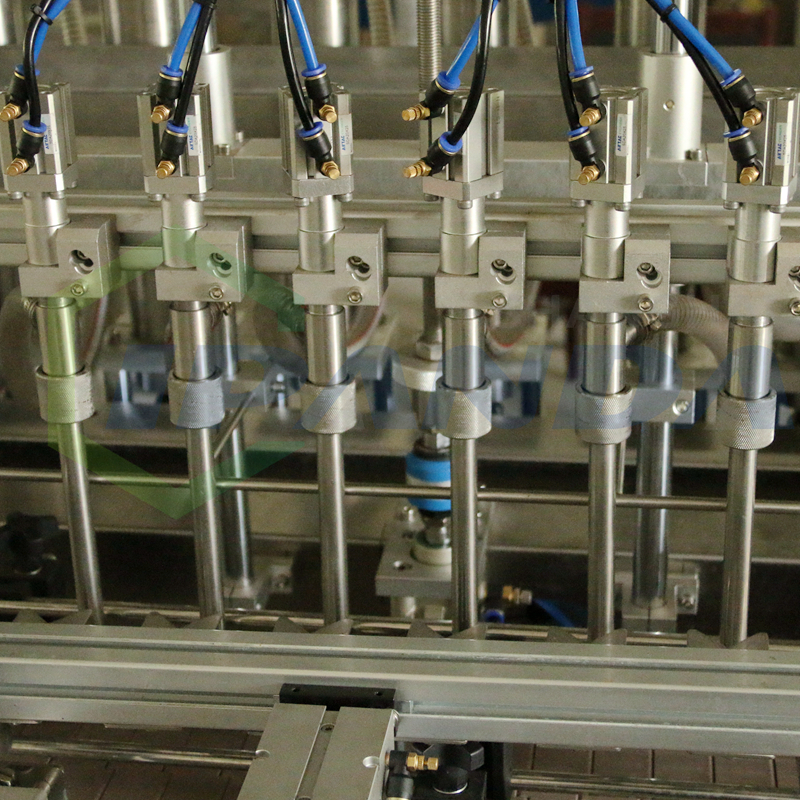

| Ho Tlatsa Nozzles | 2/4/6/8/10/12(E ikemiseditseng) |

| Sistimi ea dosing | Pompo ea piston |

| Ho Tlatsa Bokhoni | 100-5000ml(E ikemiseditseng) |

| Mofani oa Moea | 0.6-0.8MPa |

| Matla | 2.0KW |

| Boima ba 'mele | 500kg(E ikemiseditseng) |

| Boholo(mm) | 2500*1400*1900mm (E ikemiseditseng) |

1.Amohela taolo ea pele ea Sejeremane SIEMENS (Siemens) PLC ho netefatsa botsitso ba ts'ebetso ea sistimi.

2.Khetha motlakase o tsoang linaheng tse ling, likarolo tsa ho laola moea, ka ts'ebetso e tsitsitseng.

3.Sistimi ea ho lemoha lifoto e amohela lihlahisoa tsa Jeremane, tse nang le boleng bo ka tšeptjoang.

4.Lisebelisoa tse ka sehloohong tse khahlanong le ho lutla li netefatsa hore ha ho na leakage e hlahang nakong ea tlhahiso.

5.Tlhahiso ea karolo ea mantlha e amohela taolo e fapaneng ea maqhubu, ts'ebetso e latelang e amohela khokahano e khethehileng ea ho kheloha habeli.

6.Ho tlatsoa ka lebelo le phahameng ka makhetlo a mabeli ho ka qoba ts'ebetso ea ho phalla, 'me ho ka eketsa katleho ea tlhahiso haholo.

7.Mochini o le mong o ikamahanya le mefuta e mengata, phetoho e potlakileng le e bonolo.

E sebelisoa bakeng sa ho tlatsa metsi a fapaneng ka libotlolong joalo ka oli, oli ea ho pheha, oli ea soneblomo, oli ea meroho, oli ea enjine, oli ea koloi, oli ea koloi.

Piston cylinder

Ho latela litlhoko tsa bokhoni ba tlhahiso ea bareki e ka etsa silindara e fapaneng ea boholo

Mokhoa oa ho tlatsa

Ho tlatsa nozzle ho amohela bophara ba molomo oa botlolo ka tloaelo e entsoeng,

Ho tlatsa nozzle ho na le ts'ebetso ea morao, ho qoba ho lutla ha oli e nepahetseng ea lintho tse bonahalang, metsi, syrups le lisebelisoa tse ling tse nang le mokelikeli o motle.

Oli sebelisa sefate tsela valve

1. Ho hokela har'a tanka, valve ea rotaty, tanka ea boemo bohle ka sekotwana sa ho tlosa kapele.

2. Oli e amohelang oli e sebelisa li-valve tse tharo, tse loketseng oli, metsi, le thepa e nang le fuidity e ntle, valve e khethehile e etselitsoe oli ntle le ho lutla, ho netefatsa ho nepahala ho phahameng.

Amohela ts'ebeliso e matla

Ha ho na tlhoko ea ho fetola likarolo, e ka fetola kapele le ho fetola libotlolo tsa libopeho le litlhaloso tse fapaneng

Adopt Touch screen le PLC Control

Ho bonolo ho fetola lebelo / bophahamo ba modumo

ha ho na botlolo ebile ha ho mosebetsi oa ho tlatsa

taolo ya boemo le ho fepa.

Sensor ea photoelectric le taolo ea khokahano ea mamati a pneumatic, botlolo e haellang, botlolo ea tšela kaofela e na le ts'ireletso ea boiketsetso.

Lintlha tsa khampani

Re tsepamisitse maikutlo ho hlahiseng mefuta e fapaneng ea mohala oa tlhahiso ea ho tlatsa lihlahisoa tse fapaneng, joalo ka capsule, mokelikeli, paste, phofo, aerosol, mokelikeli o senyang joalo-joalo, o sebelisoang haholo liindastering tse fapaneng, ho kenyeletsoa lijo / seno / litlolo / lik'hemik'hale tsa petrochemical joalo-joalo. Mechini kaofela e hlophisitsoe ho latela sehlahisoa le kopo ea moreki.Letoto lena la mochine oa ho paka ke pale ea sebopeho, e tsitsitseng ts'ebetsong 'me e bonolo ho sebetsa.Amohela lengolo la bareki ba bacha le ba khale ho buisana ka litaelo, ho thehoa ha balekane ba botsoalle.Re na le bareki linaheng tsa Unites, Middle East, Asia Boroa-bochabela, Russia joalo-joalo 'me re fumane litlhaloso tse ntle ho bona ka boleng bo phahameng hammoho le tšebeletso e ntle.

Tšebeletso ea ka mor'a thekiso:

Re netefatsa boleng ba likarolo tse kholo nakong ea likhoeli tse 12.Haeba likarolo tse kholo li sa tsamaee hantle ntle le mabaka a maiketsetso nakong ea selemo se le seng, re tla u fa tsona ka bolokolohi kapa re u bolokele tsona.Kamora selemo, haeba o hloka ho fetola likarolo, ka mosa re tla u fa theko e ntle kapa re e boloke sebakeng sa hau sa marang-rang.Nako le nako ha u na le potso ea tekheniki ha u e sebelisa, re tla etsa sohle se matleng a rona ho u tšehetsa ka bolokolohi.

Tiisetso ea boleng:

Moetsi o tla netefatsa hore thepa e entsoe ka thepa e ntle ka ho fetisisa ea Moetsi, e nang le moetso oa boemo ba pele, e ncha, e sa sebelisoeng 'me e tsamaellana ka litsela tsohle le boleng, litlhaloso le ts'ebetso joalo ka ha ho hlalositsoe Konterakang ena.Nako ea netefatso ea boleng ke nakong ea likhoeli tse 12 ho tloha ka letsatsi la B/L.Moetsi o ne a tla lokisa mechini e kentsoeng ntle ho tefo nakong ea tiisetso ea boleng.Haeba karohano e ka ba ka lebaka la tšebeliso e fosahetseng kapa mabaka a mang a Moreki, Moetsi o tla bokella litšenyehelo tsa likarolo tsa tokiso.

Ho kenya le ho lokisa liphoso:

Morekisi o ne a tla romela lienjiniere tsa hae ho laela ho kenya le ho lokisa liphoso.Litsenyehelo li tla ba ka lehlakoreng la moreki (litekete tsa ho ea le ho khutla, litefiso tsa bolulo naheng ea bareki).Moreki o lokela ho fana ka thuso ea sebaka sa hae bakeng sa ho kenya le ho lokisa liphoso

LBH

Q1: Lihlahisoa tsa mantlha tsa k'hamphani ea hau ke life?

Palletizer, Conveyors, Filling Production line, Mechini ea ho Tiisa, Mechini ea Cap ping, Mechini ea ho Paka, le Mechini ea ho Labela.

Q2: Letsatsi la ho tlisa lihlahisoa tsa hau ke lefe?

Letsatsi la thomello ke matsatsi a 30 a tšebetso hangata boholo ba mechini.

Q3: Nako ea ho lefa ke eng?Deposit 30% esale pele le 70% pele o romella mochini.

Q4:O kae?Na ho loketse ho u etela?Re fumaneha Shanghai.Sephethephethe se bonolo haholo.

Q5:U ka tiisa boleng joang?

1.Re qetile tsamaiso le mekhoa ea ho sebetsa 'me re li latela ka thata haholo.

2.Mosebeletsi oa rona ea fapaneng o ikarabella bakeng sa ts'ebetso e fapaneng ea ts'ebetso, mosebetsi oa bona o netefalitsoe, 'me o tla lula a sebetsa ts'ebetso ena, e nang le boiphihlelo haholo.

3. Lisebelisoa tsa pneumatic tsa motlakase li tsoa lik'hamphani tse tummeng lefatšeng, tse kang Jeremane ^ Siemens, Japanese Panasonic joalo-joalo.

4. Re tla etsa teko e tiileng ea ho sebetsa ka mor'a hore mochine o felile.

Mechini ea 5.0ur e netefalitsoe ke SGS, ISO.

Q6: Na o ka rala mochini ho latela litlhoko tsa rona?Ee.Ha re khone feela ho etsa mochini ho latela setšoantšo sa hau sa technical, empa hape a ka khona ho etsa mochini o mocha ho latela litlhoko tsa hau.

Q7: Na o ka fana ka tšehetso ea tekheniki mose ho maoatle?

Ee.Re ka romella moenjiniere k'hamphaning ea hau ho theha mochini le ho koetlisa hau.