Vial Filling Line bakeng sa ho Tlatsa Botlolo e Nyenyane le Mochini oa Capping

Mohala oa tlhahiso ea ho tlatsa vial o entsoe ka mochini o hlatsoang libotlolo tsa ultrasonic, sterilizer e omisitsoeng, mochini o emisang ho tlatsa le mochini oa capping.E ka phethela ho fafatsa metsi, ho hloekisa ka ultrasonic, ho phunya lebota la ka hare le ka ntle la botlolo, ho futhumatsa, ho omisa le ho etsa sterilization, ho tlosa mohloli oa mocheso, ho pholile, ho senya botlolo, (nitrogen pre-filling), ho tlatsa, (nitrogen post-filling), stopper. unscrambling, stopper pressing, cap unscrambling, capping le mesebetsi e meng e rarahaneng, ho hlokomela tlhahiso ea othomathike ea ts'ebetso eohle.Mochine o mong le o mong o ka sebelisoa ka thoko, kapa moleng oa khokahano.Mohala oohle o sebelisoa haholo bakeng sa ho tlatsa liente tsa mokelikeli oa vial le liente tse omisitsoeng tsa phofo lifekthering tsa meriana, o ka sebelisoa le ho hlahisoeng ha lithibela-mafu, meriana ea likokoana-hloko, meriana ea lik'hemik'hale, lihlahisoa tsa mali joalo-joalo.

| Mohlala | SHPD4 | SHPD6 | SHPD8 | SHPD10 | SHPD12 | SHPD20 | SHPD24 |

| Litlhaloso tse sebetsang | 2 ~ 30ml libotlolo tsa vial | ||||||

| Ho tlatsa lihlooho | 4 | 6 | 8 | 10 | 12 | 20 | 24 |

| Bokhoni ba tlhahiso | 50-100bts/min | 80-150bts/min | 100-200bts/min | 150-300bts/min | 200-400bts/min | 250-500bts/min | 300-600bts/min |

| Sekhahla sa ho emisa ho fumana mangolo | =99% | ||||||

| Bohloeki ba moea oa laminar | 100 sehlopheng | ||||||

| Lebelo la ho pompa ka vacuum | 10m3/h | 30m3/h | 50m3/h | 60m3/h | 60m3/h | 100m3/h | 120m3/h |

| Tšebeliso ea matla | 5kw | ||||||

| Phepelo ea motlakase | 220V/380V 50Hz | ||||||

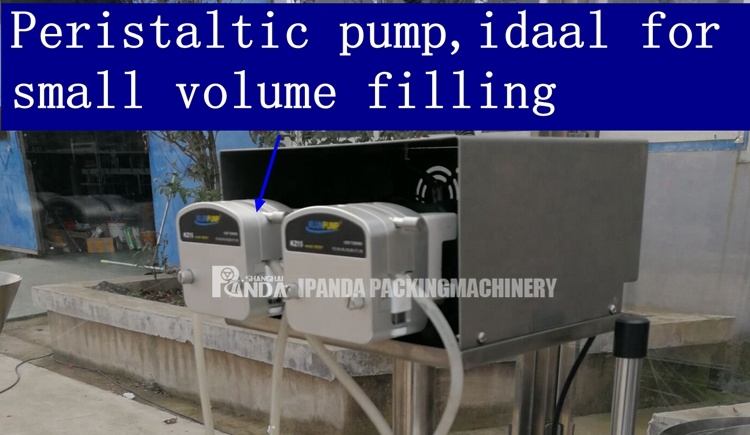

- Pompo ea Peristaltic kapa ho tlatsa pompo ea peristaltic ka nepo e phahameng, lebelo la ho tlatsa le phahame mme phoso ea ho tlatsa e nyane.

2. Sesebelisoa sa Groove cam se beha libotlolo ka nepo.Ho matha ho tsitsitse, karolo ea phetoho e ka bochabela ho fetoha.

3. Phanele ea taolo ea likonopo e bonolo ho sebetsa mme e na le degree e phahameng ea automation.

4. Ho oela ha botlolo ea koloi e hanoang ka har'a turntable, ha ho botlolo, ha ho na ho tlatsa;mochine o ema ha ho se na setopo;lialamo tsa likoloi ha

sethithi se lekaneng.

5. Hlomella ka mosebetsi oa ho bala likoloi.

6. Setifikeiti, ho kenya motlakase o tloaelehileng, tiiso ea tšireletso ha e sebetsa.

7. Optional acrylic khalase tšireletso hood le 100-sehlopha phallo laminar.

8. Ho ikhethela ho tlatsa pele le ka mor'a ho tlatsa naetrojene.

9. Mochine oohle o entsoe ho latela litlhoko tsa GMP.

Vial e kenang e ommeng (e sterilized le silicone) e fepeloa ka har'a sekoahelo 'me e tataisoa ka nepo holim'a lebanta le tsamaisang la delrin slat ka lebelo le hlokahalang la sebaka se nepahetseng ka tlase ho yuniti ea ho tlatsa.Setsi sa ho tlatsa se na le Hlooho ea ho Tlatsa, Lisyringe & Nozzles tse sebelisetsoang ho tlatsa metsi.Li-syringe li entsoe ka kaho ea SS 316 'me ka bobeli, likhalase hammoho le li-syringe tsa SS li ka sebelisoa.Ho fanoa ka Wheel ea Star e ts'oereng vial nakong ea ts'ebetso ea ho tlatsa.Sensor e fanoa.

1) Ena ke liphaephe tsa ho tlatsa, ke liphaephe tsa boleng bo phahameng tse tsoang linaheng tse ling. Ho na le li-valve holim'a phala, e tla monya metsi ka mor'a ho tlatsa hang.Kahoo ho tlatsa li-nozzles ho ke ke ha lutla.

2) Sebopeho sa li-roller tse ngata tsa pompo ea rona ea peristaltic le ho feta ho ntlafatsa botsitso le ho se be le tšusumetso ea ho tlatsa le ho etsa hore ho tlatsoa ha mokelikeli ho tsitsitse mme ho se be bonolo ho blister.E loketse ka ho khetheha bakeng sa ho tlatsa mokelikeli ka tlhokahalo e phahameng.

3) Ena ke hlooho ea aluminium Cap e tiisang.E na le rolara e tiisang tse tharo.E tla tiisa Cap ho tloha mahlakoreng a mane, kahoo Cap e tiisitsoeng e thata haholo ebile e ntle.E ke ke ea senya Cap kapa leakage Cap.