Automatic Vial Filling Stoppering le Capping Machine Line

Mohala oa tlhahiso ea ho tlatsa vial o entsoe ka mochini o hlatsoang libotlolo tsa ultrasonic, sterilizer e omisitsoeng, mochini o emisang ho tlatsa le mochini oa capping.E ka phethela ho fafatsa metsi, ho hloekisa ka ultrasonic, ho phunya lebota la ka hare le ka ntle la botlolo, ho futhumatsa, ho omisa le ho etsa sterilization, ho tlosa mohloli oa mocheso, ho pholile, ho senya botlolo, (nitrogen pre-filling), ho tlatsa, (nitrogen post-filling), stopper. unscrambling, stopper pressing, cap unscrambling, capping le mesebetsi e meng e rarahaneng, ho hlokomela tlhahiso ea othomathike ea ts'ebetso eohle.Mochine o mong le o mong o ka sebelisoa ka thoko, kapa moleng oa khokahano.Mohala oohle o sebelisoa haholo bakeng sa ho tlatsa liente tsa mokelikeli oa vial le liente tse omisitsoeng tsa phofo lifekthering tsa meriana, o ka sebelisoa le ho hlahisoeng ha lithibela-mafu, meriana ea likokoana-hloko, meriana ea lik'hemik'hale, lihlahisoa tsa mali joalo-joalo.

| Mohlala | SHPD4 | SHPD6 | SHPD8 | SHPD10 | SHPD12 | SHPD20 | SHPD24 |

| Litlhaloso tse sebetsang | 2 ~ 30ml libotlolo tsa vial | ||||||

| Ho tlatsa lihlooho | 4 | 6 | 8 | 10 | 12 | 20 | 24 |

| Bokhoni ba tlhahiso | 50-100bts/min | 80-150bts/min | 100-200bts/min | 150-300bts/min | 200-400bts/min | 250-500bts/min | 300-600bts/min |

| Sekhahla sa ho emisa ho fumana mangolo | =99% | ||||||

| Bohloeki ba moea oa laminar | 100 sehlopheng | ||||||

| Lebelo la ho pompa ka vacuum | 10m3/h | 30m3/h | 50m3/h | 60m3/h | 60m3/h | 100m3/h | 120m3/h |

| Tšebeliso ea matla | 5kw | ||||||

| Phepelo ea motlakase | 220V/380V 50Hz | ||||||

1.Mohala oa tlhahiso ea ho tlatsa li-vial o kopana le litlhoko tse ncha tsa GMP, 'me phello ea ho hloekisa e kopana le litekanyetso le litlhoko tse ncha tsa Pharmacopoeia.

2.Mohala oohle o ka amohela sebopeho se otlolohileng kapa sebopeho sa sebopeho sa L sa lebota ho isa leboteng ho fokotsa kotsi ea tšilafalo le ho netefatsa boemo ba aseptic.

3.Tlhahiso e sebetsang: 1ml-100ml vial (ho ea ka tlhokahalo ea mosebedisi)

4.Bokhoni ba tlhahiso: 1000-36000BPH

5.Palo ea hlooho ea ho tlatsa: 1-20, e lokelang ho khethoa ho latela tlhahiso

6.Ho Tlatsa Ho nepahala ha mochine oa ho tlatsa vial: ≤ ± 1% (ho ea ka litšobotsi tsa lithethefatsi)

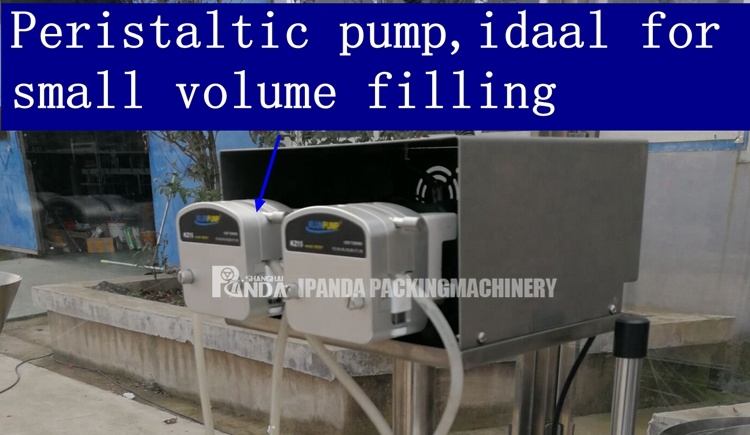

7.Khetho ea lipompo tse fapaneng tsa ho tlatsa: pompo ea khalase, pompo ea tšepe, pompo ea peristaltic, pompo ea ceramic;

8.Capping sekhahla se tšoanelehang: ≥99.9%

9.Mohaho o tiileng le o bonolo, o nka sebaka se fokolang;

Ts'ebetso ea 10.Stable sehlahisoa, ts'ebetso e bonolo le e ka tšeptjoang, ponahalo e ntle;

11.Boemo bo phahameng ba boiketsetso, ho hlokahala basebelisi ba fokolang;

Vial e kenang e ommeng (e sterilized le silicone) e fepeloa ka har'a sekoahelo 'me e tataisoa ka nepo holim'a lebanta le tsamaisang la delrin slat ka lebelo le hlokahalang la sebaka se nepahetseng ka tlase ho yuniti ea ho tlatsa.Setsi sa ho tlatsa se na le Hlooho ea ho Tlatsa, Lisyringe & Nozzles tse sebelisetsoang ho tlatsa metsi.Li-syringe li entsoe ka kaho ea SS 316 'me ka bobeli, likhalase hammoho le li-syringe tsa SS li ka sebelisoa.Ho fanoa ka Wheel ea Star e ts'oereng vial nakong ea ts'ebetso ea ho tlatsa.Sensor e fanoa.

1) Ena ke liphaephe tsa ho tlatsa, ke liphaephe tsa boleng bo phahameng tse tsoang linaheng tse ling. Ho na le li-valve holim'a phala, e tla monya metsi ka mor'a ho tlatsa hang.Kahoo ho tlatsa li-nozzles ho ke ke ha lutla.

2) Sebopeho sa li-roller tse ngata tsa pompo ea rona ea peristaltic le ho feta ho ntlafatsa botsitso le ho se be le tšusumetso ea ho tlatsa le ho etsa hore ho tlatsoa ha mokelikeli ho tsitsitse mme ho se be bonolo ho blister.E loketse ka ho khetheha bakeng sa ho tlatsa mokelikeli ka tlhokahalo e phahameng.

3) Ena ke hlooho ea aluminium Cap e tiisang.E na le rolara e tiisang tse tharo.E tla tiisa Cap ho tloha mahlakoreng a mane, kahoo Cap e tiisitsoeng e thata haholo ebile e ntle.E ke ke ea senya Cap kapa leakage Cap.

Shanghai iPanda Intelligent Machinery Co., Ltd. e ikemiselitse ho sebelisa thepa ea R&D, ho etsa le ho hoeba ka mefuta e fapaneng ea mechini ea ho paka.Ke khoebo ea theknoloji e phahameng e kopanyang moralo, tlhahiso, khoebo, le R&D.Thepa ea k'hamphani ea R&D le sehlopha sa baetsi ba thepa e na le boiphihlelo ba lilemo tse fetang 10 indastering, e amohela litlhoko tse ikhethang ho tsoa ho bareki le ho fana ka mefuta e fapaneng ea mela ea kopano ea othomathike kapa ea othomathike bakeng sa ho tlatsa.Lihlahisoa li sebelisoa haholo lik'hemik'hale tsa letsatsi le letsatsi, meriana, petrochemical, lijo, lino le masimo a mang.Lihlahisoa tsa rona li na le 'maraka Europe, United States le Asia Boroa-bochabela, joalo-joalo li hapile bareki ba bacha le ba khale ka ho tšoanang.

Sehlopha sa talenta sa Panda Intelligent Machinery se bokella litsebi tsa lihlahisoa, litsebi tsa thekiso le basebetsi ba tšebeletso ea ka mor'a thekiso, 'me ba tšehetsa filosofi ea khoebo ea."Boleng bo botle, tšebeletso e ntle, botumo bo botle".Re tla tsoelapele ho ntlafatsa boemo ba khoebo ea rona, ho holisa maemo a rona a khoebo, le ho ikitlaelletsa ho fihlela litlhoko tsa bareki.

LBH

Q1: Lihlahisoa tsa mantlha tsa k'hamphani ea hau ke life?

Palletizer, Conveyors, Filling Production line, Mechini ea ho Tiisa, Mechini ea Cap ping, Mechini ea ho Paka, le Mechini ea ho Labela.

Q2: Letsatsi la ho tlisa lihlahisoa tsa hau ke lefe?

Letsatsi la thomello ke matsatsi a 30 a tšebetso hangata boholo ba mechini.

Q3: Nako ea ho lefa ke eng?Deposit 30% esale pele le 70% pele o romella mochini.

Q5: U fumaneha hokae?Na ho loketse ho u etela?Re fumaneha Shanghai.Sephethephethe se bonolo haholo.

Q6: U ka netefatsa boleng joang?

1.Re qetile tsamaiso le mekhoa ea ho sebetsa 'me re li latela ka thata haholo.

2.Mosebeletsi oa rona ea fapaneng o ikarabella bakeng sa ts'ebetso e fapaneng ea ts'ebetso, mosebetsi oa bona o netefalitsoe, 'me o tla lula a sebetsa ts'ebetso ena, e nang le boiphihlelo haholo.

3. Lisebelisoa tsa pneumatic tsa motlakase li tsoa lik'hamphani tse tummeng lefatšeng, tse kang Jeremane ^ Siemens, Japanese Panasonic joalo-joalo.

4. Re tla etsa teko e tiileng ea ho sebetsa ka mor'a hore mochine o felile.

Mechini ea 5.0ur e netefalitsoe ke SGS, ISO.

Q7: Na o ka rala mochini ho latela litlhoko tsa rona?Ee.Ha re khone feela ho etsa mochini ho latela setšoantšo sa hau sa technical, empa hape a ka khona ho etsa mochini o mocha ho latela litlhoko tsa hau.

Q8: Na o ka fana ka tšehetso ea tekheniki mose ho maoatle?

Ee.Re ka romella moenjiniere k'hamphaning ea hau ho theha mochini le ho koetlisa hau.